At the Tokyo Motor Show in 2017, Toyota announced that they would commericalize all-solid-state battery technology for EVs by early 2020s. Since then, all-solid-state batteries have been considered a crucial component in the evolution of the EV industry. However, can we rely upon this technology as much as Toyota claims? To answer this question, I interviewed Mr. Toru Amazutsumi, a specialist in the field of battery research.

Original post; ‘電気自動車の進化に必須といわれる「全固体電池」は実用化できない?‘ by Ryuichi Kino On “EVsmart blog”

“There is nothing good about all-solid-state batteries.”

I met Mr Amazutsumi at Awaji island, located near Kobe. Driving there in a Tesla Model 3, I had originally planned to discuss lithium ion batteries, but the intriguing topic of all-solid-state batteries became the main theme of our talk.

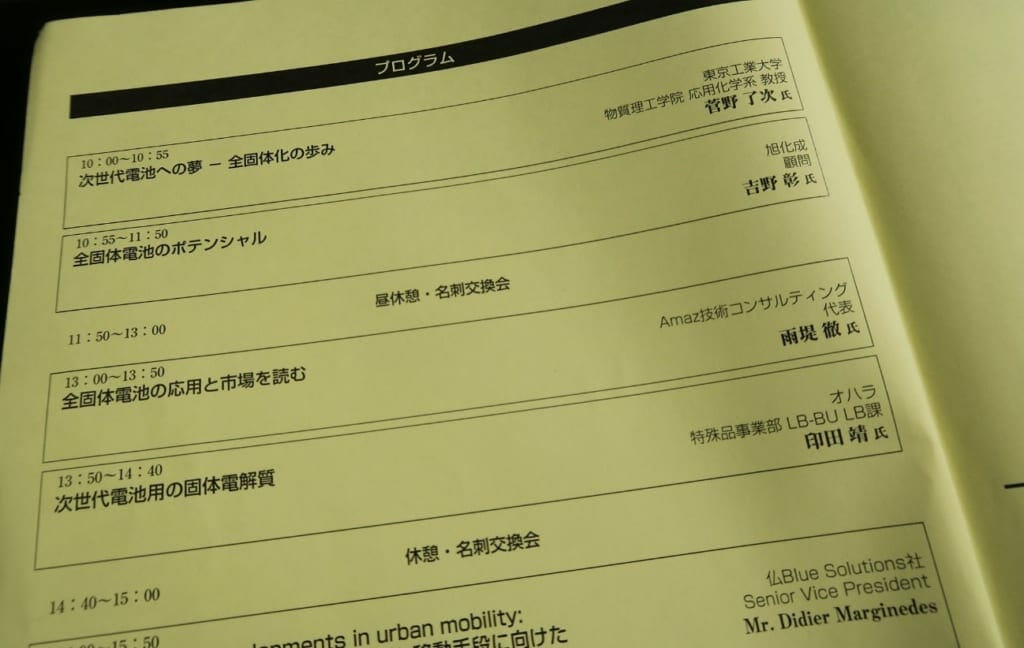

Mr. Amazutsumi used to work for Sanyo Electric, where he led development of lithium ion batteries, a technology later employed by Tesla in their EVs. He left Sanyo Electric in 2010 to establish his own company, Amaz Techno-consultant, based in Awaji island. This company offers consulting services for the entire process of battery development, from materials to production.

Toru Amazutsumi

Founder of Amaz Techno-consultant, LLC.

MSc in Inorganic industrial chemistry

PhD in Electrochemical engineering

He has worked in battery development throughout his career. While was working for SANYO, he was responsible for early contracts to provide lithium ion batteries to Tesla.

What is the advantage of all-solid-state batteries?

All-solid-state batteries is a hot topic in the EV industry today, and particularly in Japan. Toyota most recently mentioned it at their technology conference in June 2019, a few years after their earlier major announcement in 2017. In September, Toyota revealed that it would provide electrified personal mobility vehicles, powered with all-solid-state batteries, at the Tokyo 2020 Olympics.

Toyota’s plan has motivated the New Energy and Industrial Technology Development Organization (NEDO) to fund a related public project, investing 10 billion yen (9 million US dollars) between 2018 to 2022.

With both public and private sectors in Japan supporting this technology, and recent media reports praising all-solid-state batteries as a safer and more efficient form of battery, there must be clear advantages to its widespread adoption.

What does Mr. Amazutsumi think?

───What aspects of all-solid-state batteries make them superior?

“It is not determined that they are superior to others. There are no specific explanations as to why it is a better solution.”

───What?

“Everybody thinks all-solid-state batteries are excellent because of of Toyota’s recent claims, right? I would interpret Toyota is trying to say they cannot produce useable EVs unless they develop all-solid-state batteries. I think this is their excuse to procrastinate producing EVs. Nobody has given any specific explanations why all-solid-state batteries are good. Everybody knows Toyota is a great car manufacture, but they are not a great battery manufacture.”

───I hear that batteries become lighter?

“Why do you think they become lighter?”

───Because energy density increases.

“How can it increase? There is no reason for that. It can decrease, but not increase. Solid substances have heavier relative density to liquid substances.”

───Do you mean, nothing changes if other materials such as electrodes are the same?

“That’s right. For instance, there is the claim that all-solid-state electrolytes permit the use of cathode/anode active materials that have higher energy density, in which case ‘energy density is increased’. But this is not plausible. There is no way energy density gets increased only because electrolyte is changed to solid from liquid. Electrolytes cannot change capacitance.”

Mr. Amazutsumi appeared at a seminar in 2016 titled ‘The frontline of all-solid-state batteries’ alongside with a Nobel prize winner Akira Yoshino. His talk shared the same theme as this interview.

Solid-state batteries were one of main objects in research 30 years ago

I was slightly shocked to hear his criticisms but, even for an amateur like myself, he makes a convincing point. First of all, all-solid-state batteries are not a new technology.

“Everyone thinks all-solid-state batteries is a new technology. However, development of it was a leading object for battery researchers about 30 years ago. All researchers in my generation have experience in solid-state electrolyte technology.

All-solid-state batteries with small capacities have existed for a long time. For example, they are used for pacemakers, used to treat abnormal heart rhythms. As pacemakers are inserted inside human bodies, liquid should not leak at any cost. That was 30 years ago.”

Mr. Amazutsumi also thinks the name ‘all-solid-state’ is slightly strange.

“Research on all-solid-state batteries has scaled down since Sony released a lithium polymer battery with has a gel-state electrolyte (Sony has since sold its battery department to Murata manufacturing Co, Ltd in 2017). More than a half of the existing solid-state batteries in the market now are polymer batteries. Is polymer not a solid substance? If you define polymer as solid-state, it has already spread into the market. One example, recently released by Kyocera, is classified as a “semi-solid lithium ion battery.”

The lithium polymer batteries from Sony prevented liquid leakage by using gel-state electrolyte, also they did not use metal for the battery exterior in order to make products smaller and lighter.

Moreover, the electrodes of Kyocera’s batteries utilize a material similar to clay, which was invented by American start-up 24M, and which 24M claims are a semi solid material.

24M Partner Kyocera to Validate Process for Mass Production

Mr. Amazutsumi further points out:

“I personally think lithium polymer batteries from Sony can be defined as solid-state batteries. Though it is not all-solid state, my point is that whether liquid or solid state, it doesn’t make that much difference. Furthermore, Sony made polymer batteries in a laminated form. They claimed that this technology was made possible because it was in solid state. However, laminated batteries nowadays contain not solid but liquid electrolyte. This means solid-state is not an advantage anymore. Unless researchers find a clear advantage, I don’t see why it has to be solid-state.”

There are barely any people pointing out problems with it

Mr. Amazutsumi suggests the biggest problem with all solid-state batteries as follows.

“The biggest problem with all-solid-state batteries is how you secure and maintain contact area between solid surfaces. Liquid electrolyte provides a big contact surface for electrode. On the other hand, solid electrolyte makes it difficult. Nobody focuses on this issue. People talk about only electrolyte but not interface.”

“A researcher of Tokyo Institute of Technology claims that (solid-state) electrolyte has higher conductivity, but this is not an issue here. Electrolyte, cathode and anode together determine how they transfer ions. Contact area must be maintained for ions to travel, and at this point, you must consider the mass production of these batteries. For example, Hitachi Zosen Corporation has tried to press solid surfaces with high pressure to expand contact area. However, the energy density still remains too low for commercial use. This is the reality.”

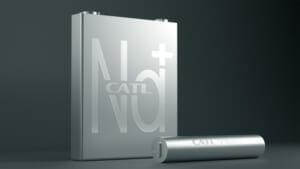

This June, Murata Manufacturing announced that they invented all-solid-state batteries with the biggest capacity in the industry. Its usage is for small goods such as wearable devices but not products with big capacities and output like EVs.

“In the lab, they are making very thin batteries with the thickness of several micrometers. It is like an evaporation coating of electrolyte. They are not useful unless they stay that thin. I asked how they could attempt mass production with much bigger capacities, and their answer was to build thousands of layers. That is impossible since efficiency would be poor, and the energy density actually decreases.”

“Cathode/anode electrodes of battery expand when they are charged and shrink when discharged. If its electrolyte is solid, it cannot expand/shrink well. Therefore, while I wouldn’t say all-solid-state batteries are impossible, since they are produced in the lab, there have been insurmountable challenges in bringing it to a mass production for the last 30 years.”

Mr. Amazutsumi imported a Tesla Model S from the US before its launch in Japan.

Researchers are snatched for this research

Mr. Amazutsumi’s story reminds me of fuel cell vehicles. In a report by the Ministry of Economy, Trade and Industry, the Japanese government expected 50,000 FCVs on its roads by 2010, and 5 million by 2020. As of March 2019, there are only about 3,000 FCVs, and 1/3 them are in Aichi, where Toyota is based. It turns out that FCVs have various issues, such as the endurance of fuel cell stack, and the establishment of infrastructure, which have not been resolved in the past 20 years. I personally thought the ambition behind FCV was great, but such unrealistic expectations can lead society in the wrong direction.

As a researcher, Mr. Amazutsumi worries that the field of all-solid-state batteries attracts too many researchers due to the accumulation of public interest and funding.

“Toyota can carry out research on all-solid-state batteries as much as they want by themselves. But it becomes a problem when they involve others, including valued researchers. Many Japanese battery researchers have shifted into all-solid-state batteries in fact. I hear more and more people talking about it at the annual battery conference by The Electrochemical Society of Japan in recent years.”

“It is often said that all-solid-state batteries are safer, but it does not mean that liquid lithium ion batteries are unsafe. They are already sufficient, so who wants to buy more expensive, lower quality batteries like all-solid-state?”

“I believe that Toyota cannot commit to a single technology in their search for a next-generation battery solution, so they are trying a variety of experiments. Indeed, I think it is important to maintain basic research in lithium ion batteries and all-solid-state batteries. However, it is irresponsible to talk as if they could be expanded to mass production in the near future. There are few researchers in the battery field, and they are highly influenced by Toyota. Meanwhile, important research, such as the material development of cathodes, is being neglected. As Toyota is very influential, I would like them to focus on more realistic matters. I feel they are dragging down the entire battery research field in Japan.”

I feel Mr.Amazutsumi’s harsh criticism should be widely discussed.

The Japanese have been gripped by all-state-batteries fever. For instance, a research company Fuji Keizai, based in Tokyo, reported that the market size of all-solid-state batteries was 2.1 billion yen (19 million US dollars) in 2018, and is expected to grow to 2,787 billion yen (25.6 billion US dollars) in 2035.

Toyota has not unveiled in detail how far their research in all-solid-state batteries has advanced. It would be great if they were to announce a significant development that can convince even Mr. Amazutsumi. However, according to him, who has devoted his entire working life to battery research, there is neither a clear advantage, nor a pathway to mass production, of all-solid-state batteries in the EV industry.

It is nice to talk about dreams, but it is crucial to maintain realistic expectations. I hope all-solid-state batteries do not end up as chaotic as‘A Midsummer Night’s Dream’.

A pedal car version of Model S at Mr. Amazutsumi’s office.

コメント

コメント一覧 (4件)

To have dreams is a good thing. Many researchers or scientists have produced innovations through their dreams. But it seems business community and government highly dream about the all-solid-state batteries in Japan recently. Scientific viewpoint is a necessity.

VERY few references to foreign research and developments in the field of solid state and dry cell batteries. Another huge limitation in Japan is that researchers are still focused on domestic efforts, trying to keep existing tech for as long as they can profit from it. This was a point of contention between Panasonic and Tesla, Toyota and Tesla, etc.

I can appreciate Amazutsumi’s skepticism and agree that Toyota has been in stasis for quite some time, while Nissan pressed forward with BEVs. Tesla has moved forward with dry cell battery tech in San Diego, CA while simultaneously working with Chinese production and battery tech. We’ll see how that turns out, of course. But, for now, Tesla’s valuation seems to be evidence of a market that wants to see technological advancement. So, let’s go Japan!!!!!!!!

Thank you for your comment, Daren! I agree that Japanese people tend to stick to their homegrown tech – I call it “my baby shokogun” (shokogun = syndrome). We, Japanese, try to take good care of our babies!

Time to learn more wider perspective and be open to foreign things.

Increasing “ion transport number” is one of reason why they are developing all solid state battery. We can easy to find some research about this by keyword “single ion conduct”,”ion transport number”….